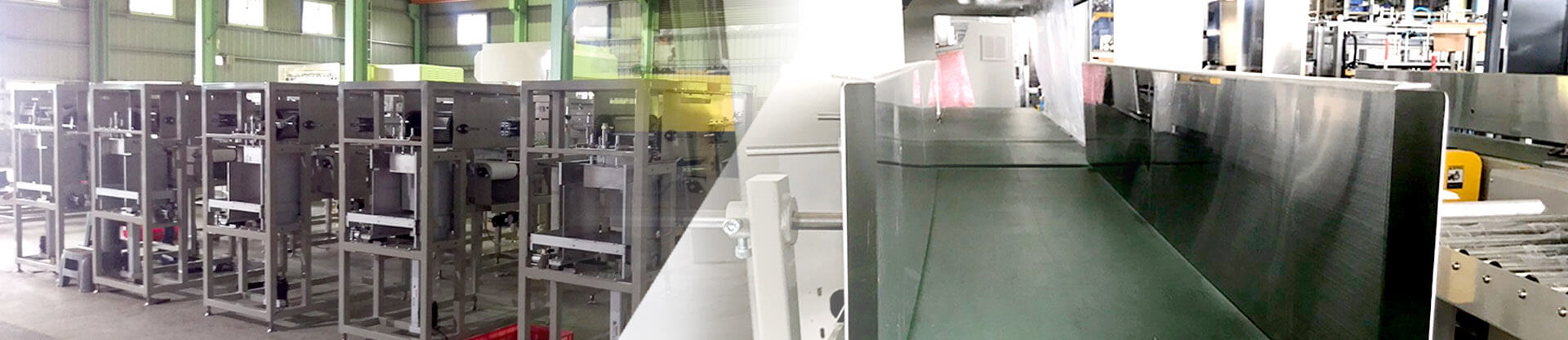

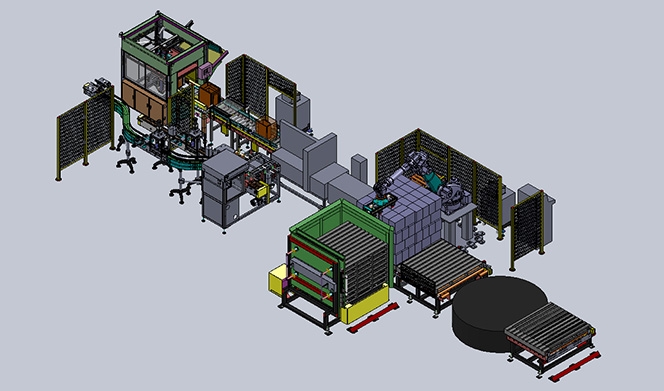

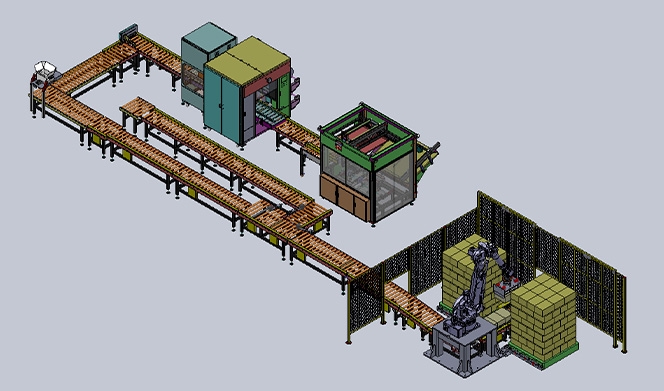

AUTOMATED PACKAGING LINES

LONG DURABLE MACHINERY CO., LTD. offers cutting-edge automated packaging lines designed to revolutionize your packaging processes, ensuring efficiency and cost-effectiveness. Our packaging line equipment systems are tailored to meet the diverse needs of various industries, from food and beverage to manufacturing and logistics.

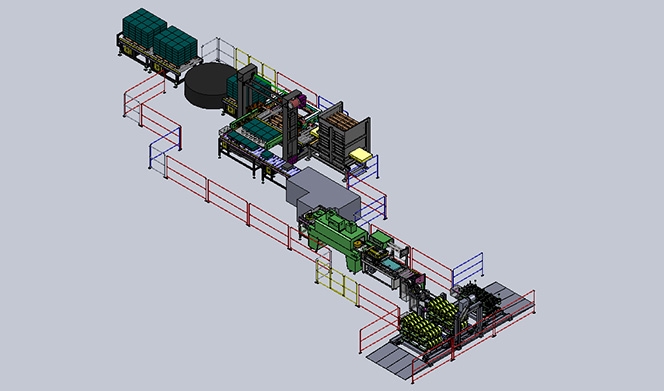

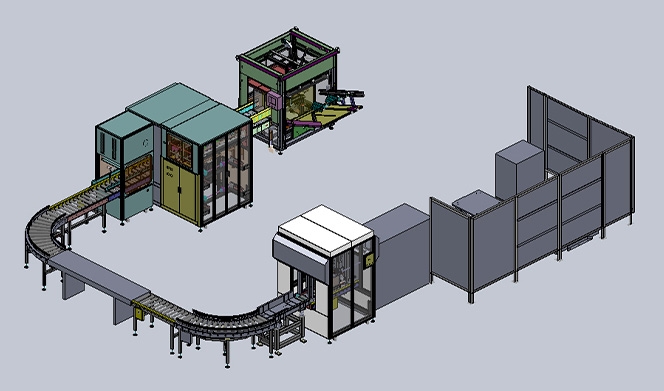

Key advantages of our automated packaging lines include custom design solutions that cater to unique packaging challenges. We provide a full packing system integration, utilizing advanced technologies such as the Robot arm, ensuring precision and reliability in every operation. Our expertise extends from the initial design and programming to complete plant integration, optimizing your entire packaging line automation workflow.

Our automatic packing line solutions are ideal for a wide range of applications, including CO2 packing line, noodle packing line, cups packing line, sesame oil packing line and jelly packing line. Each line is engineered to handle specific product types, enhancing productivity and ensuring consistent quality. By automating your packaging line, you can significantly reduce labor costs, minimize errors, and increase throughput.

Partnering with Long Durable means you benefit from our extensive experience and commitment to excellence. We understand the complexities of packaging automation and provide comprehensive solutions that address every aspect of your packaging needs. Whether you require a single automation process or a complete factory solution, our team is ready to deliver.

Explore the potential of our automatic packaging lines and transform your packaging operations. Contact us today to discuss your specific requirements and discover how we can help you achieve new levels of efficiency and competitiveness in your industry.

Long Durable's Automated Packaging Lines Common Quickly Q&A?

Here’s how packaging line automation helps companies improve efficiency, reduce costs, and stay competitive:

-

Increased Productivity and Speed

Automated systems operate continuously at high speeds, significantly increasing output. Businesses can meet rising demand efficiently without overextending their workforce.

-

Consistent Quality and Precision

Automation ensures every package is completed with uniform precision. With the help of sensors and machine vision, packaging line equipment minimizes human error and maintains strict quality control.

-

Lower Labor Costs

By automating repetitive and time-consuming tasks, companies can reduce their dependence on manual labor. This enables better workforce allocation and long-term payroll savings.

-

Enhanced Workplace Safety

Packaging line automation reduces the risk of injuries from repetitive motion, heavy lifting, and exposure to hazardous materials, creating a safer working environment.

-

Reduced Material Waste

Automated packaging systems use just the right amount of packaging material, helping minimize waste and lower material costs—an added benefit for sustainability efforts.

-

Optimized Resource Utilization

Automation streamlines the use of both labor and materials, improving overall operational efficiency and supporting lean manufacturing practices.

-

Increased Uptime and Reliability

High-quality packaging line equipment is built for durability and long runtime, with minimal maintenance requirements. This ensures consistent production with fewer interruptions.

-

Better Customer Satisfaction

Faster order fulfillment, consistent packaging quality, and improved protection during shipping lead to happier customers and fewer returns.

Modern automated packaging lines are engineered with the flexibility to efficiently process products made from a wide range of materials, including glass, plastic, metal, paper, and fragile composites. Through advanced packaging line automation and intelligent handling systems, each item is treated with the care and precision it requires.

-

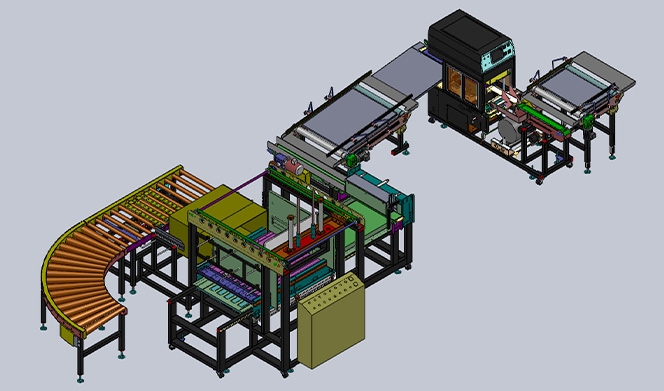

Adaptable Robotic Arms and Grippers

Robotic components in automated packaging lines are fitted with a variety of interchangeable grippers—such as vacuum suction, soft-touch robotic fingers, or mechanical clamps. These end-effectors are selected based on the product’s material and fragility, enabling safe and efficient handling regardless of shape or weight.

-

Gentle Conveying and Sorting Mechanisms

Fragile or lightweight items are transported through gentle conveyor systems designed to reduce impact and vibration. Specialized modules, such as bottom-loading or soft-drop conveyors, are used in automatic packing lines to prevent damage during sorting and placement.

-

Automated Quality Control and Inspection

Integrated sensors and high-resolution cameras monitor key checkpoints—ensuring proper sealing, accurate labeling, and overall package integrity. These systems ensure that products of all materials are securely packaged and ready for shipping without risk of damage.

-

Flexible Process Control via Smart Software

With programmable logic controllers (PLCs) and adaptive algorithms, automated packaging lines can adjust parameters such as sealing pressure, conveyor speed, pack density, and temperature settings in real time. This ensures optimal handling for each material type without manual intervention.

Modern automated packaging lines are engineered to manage products of different sizes and weights with precision and efficiency. By combining adaptable machinery, smart sensors, and advanced software, packaging line automation ensures consistent quality and flexibility across diverse packaging requirements. Here’s how an automatic packing line manages this complexity:

-

Sensors and Vision Systems

Integrated weight sensors, 3D scanners, and machine vision cameras allow automated packaging lines to detect the exact dimensions and weight of each item entering the line. This real-time data guides the system in selecting the optimal packaging method and materials for each product—ensuring both protection and efficiency.

-

Flexible Packaging Machinery

Core components of the automatic packing line—including case packers, cartoners, and palletizing robots—are built for versatility. These machines can dynamically adjust grip strength, stacking patterns, and placement strategies to handle a wide range of package sizes and product weights without sacrificing speed or safety.

-

Adaptive Process Control

With programmable logic controllers (PLCs) and smart software, packaging line automation can automatically modify conveyor speeds, sealing pressure, and fill volumes based on each product’s specifications. This ensures consistent performance even when handling mixed product loads.

-

Integrated Checkweighers and Quality Assurance

To maintain accuracy and compliance, automated packaging lines incorporate checkweighers and multihead weighers that continuously verify product weights. These systems reduce the risk of overfill or underfill, minimize waste, and improve overall quality control through advanced data analytics.

-

On-Demand and Customizable Packaging

Many automatic packing lines feature on-demand packaging systems that create custom-sized cartons or containers tailored to each product’s dimensions. This not only improves material efficiency but also helps reduce shipping volume—ideal for e-commerce and high-mix, low-volume operations.

-

Rapid Changeover Capabilities

One of the key strengths of packaging line automation is its ability to quickly switch between different product formats. Automated lines support fast changeovers with minimal downtime, allowing manufacturers to respond rapidly to shifting production needs or SKU variations.